Sponsrat innehåll från congatec GmbH

Real-time Ethernet for all

The real-time processing of data for OPC UA, as well as many other tactile Internet applications, are coming up fast as important new areas of industrial communication. This is due in large part to the emergence of 5G technologies and the increase in factories installing 10+ GbE networks. The stranglehold that many established proprietary industrial Ethernet installations have had for so many years is now starting to be released by Time-Sensitive Networking (TSN), which is ushering in these real-time applications.

Classic Fieldbus vs. Industrial Ethernet

Fieldbuses have been a crucial element in Industrial communication systems, and as we look ahead to the coming years, it’s safe to say that this trend will continue. But with the coming of extremely demanding Industrial to loT and Industry 4.0 applications, the importance of fieldbuses will certainly decrease. The reason is that classic fieldbus installations find it difficult to deal with the bandwidth and performance requirements of these real-time applications. The connectivity of cloud and fog at the edge must also be considered, as well as the vertical exchange of data right to the top of the automation pyramid. If the demands of all of these factors are considered, in addition to the continuing introduction of industrial PC technology, it’s easy to see that the dominance of fieldbus within industrial communication systems will need to be replaced.

Precise time synchronization is an important requirement of the tactile Internet. The Pico-ITX board from congatec is an industrial computer platform that supports Time-Sensitive Networking, which is crucial in ensuring precise synchronization. The Precision Time Protocol handles time synchronization between nodes, with a master responsible for setting the time. The clocks of individual slaves are synchronized within two-digit nanosecond accuracy.

Taking their place is the Industrial Ethernet, a new, second generation of fieldbus that can handle the demands of today’s cutting edge industrial communication systems. The importance and viability of this new generation was confirmed by a 2019 market study from HMS, which found that Industrial Ethernet is supported by about 59% of recently installed nodes for factory automation, but only around 35% of recently installed nodes connect with the classic fieldbus. This is quite a revelation, and certainly a strong confirmation of where things are headed.

Industrial Ethernet applications are extremely powerful and efficient, as a common transmission medium is shared by both real-time and IT data. The advantage of Industrial Ethernet, compared to fieldbus, is that the size of the network and connected devices is practically unlimited. The continuity of data throughout the whole production area is guaranteed, due to network connectivity that is consistent and fully integrated. Securing and firmly controlling the network can be carried out with the implementation of security protocols and IT security management. But fieldbuses are not made obsolete, as they can be used in the field as subordinate networking systems, if the proper gateways are established.

The decline of proprietary standards

A major disadvantage of the current field of Industrial Ethernet variants is their incompatibility with one another, due to each having their own proprietary solution. This same problem is found with the range of available fieldbus systems. If one looks closer at the history of development, it’s no big mystery why this situation exists. When standards for the first fieldbus generation were created, different companies and interest groups introduced differing standards that met their own specific requirements. With the launching of the second fieldbus generation, the same players are still following their own proprietary roadmap.

A few examples that can be mentioned is CANopen, which is an Industrial Ethernet solution based on the CAN fieldbus, as well as the Profibus-based solution called Profinet. Another is Modubus/TCP, which is a version of Modus. More examples exist, but this gives a good idea of the different standards that one is faced with when surveying the second generation of fieldbus solutions.

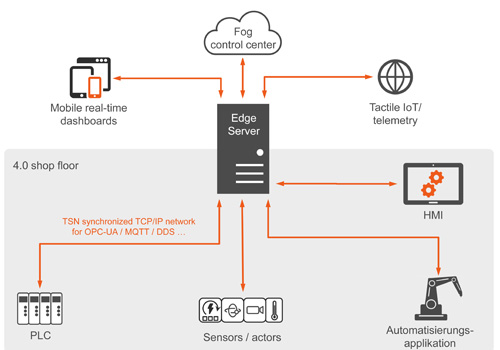

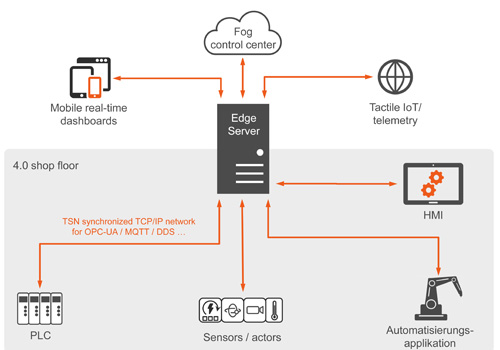

TSN synchronized TCP/IP network

Precise time synchronization is an important requirement of the tactile Internet. The Pico-ITX board from congatec is an industrial computer platform that supports Time-Sensitive Networking, which is crucial in ensuring precise synchronization. The Precision Time Protocol handles time synchronization between nodes, with a master responsible for setting the time. The clocks of individual slaves are synchronized within two-digit nanosecond accuracy.

Taking their place is the Industrial Ethernet, a new, second generation of fieldbus that can handle the demands of today’s cutting edge industrial communication systems. The importance and viability of this new generation was confirmed by a 2019 market study from HMS, which found that Industrial Ethernet is supported by about 59% of recently installed nodes for factory automation, but only around 35% of recently installed nodes connect with the classic fieldbus. This is quite a revelation, and certainly a strong confirmation of where things are headed.

Industrial Ethernet applications are extremely powerful and efficient, as a common transmission medium is shared by both real-time and IT data. The advantage of Industrial Ethernet, compared to fieldbus, is that the size of the network and connected devices is practically unlimited. The continuity of data throughout the whole production area is guaranteed, due to network connectivity that is consistent and fully integrated. Securing and firmly controlling the network can be carried out with the implementation of security protocols and IT security management. But fieldbuses are not made obsolete, as they can be used in the field as subordinate networking systems, if the proper gateways are established.

The decline of proprietary standards

A major disadvantage of the current field of Industrial Ethernet variants is their incompatibility with one another, due to each having their own proprietary solution. This same problem is found with the range of available fieldbus systems. If one looks closer at the history of development, it’s no big mystery why this situation exists. When standards for the first fieldbus generation were created, different companies and interest groups introduced differing standards that met their own specific requirements. With the launching of the second fieldbus generation, the same players are still following their own proprietary roadmap.

A few examples that can be mentioned is CANopen, which is an Industrial Ethernet solution based on the CAN fieldbus, as well as the Profibus-based solution called Profinet. Another is Modubus/TCP, which is a version of Modus. More examples exist, but this gives a good idea of the different standards that one is faced with when surveying the second generation of fieldbus solutions.

TSN synchronized TCP/IP network

Industrial applications for TSN synchronized tactile Internet are not confined to cloud-based control station technology and remote-controlled robots that carry out tele-surgery. They are increasingly making their way into conventional control solutions that previously relied on classic fieldbuses and Industrial Ethernet applications, due to a significant increase in scalability and bandwidth, as well as the advantages of manufacturer neutrality and higher flexibility

When the time comes to migrate to Industrial Ethernet, or even combining fieldbus and various applications of Industrial Ethernet, problems can be encountered due to constrictions imposed by proprietary solutions. These can include not only licensing issues, but also the inability to achieve trouble-free factory connectivity. Connectivity issues stem from the requirement of having dedicated hardware for most solutions, such as the need for a specific Industrial Ethernet controller. Only one solution, the EtherCAT protocol, stands out in the proprietary forest of Industrial Ethernet solutions by offering real-time networking using standard Ethernet controllers.

Making the hyper jump from Ethernet to Industrial Ethernet

A major hurdle for second fieldbus generation developers was achieving real-time communication for the various real-time classes, with each requiring different response times. This challenge cut across all fieldbus variants due to deterministic transmission rates not being supported by conventional IT Ethernet that complies with IEEE 802.3. Even if we consider that transmission rates are relatively high between variants, irregular delays in data traffic are many times encountered as the resolution of data collisions are controlled by a mechanism that is based on the random principle.

To combat this problem, Real-time Ethernet solutions add their own real-time protocol stacks that are notably smaller in size, thereby preventing collisions of data streams. The protocol stacks are marked in the Ethernet protocol layer as a specific “EtherType”, which allows for prioritization, so data that is not so time-critical can be sent over the mailbox channel in parallel. In this way, real-time traffic is not disturbed, and at the same time guaranteeing consistently seamless Ethernet connectivity for standard TCP/IP communication, such as web servers, e-mail, etc.

Hard real-time applications live up to their name by demanding exact deterministic response times, which many times require almost zero delays and clock cycles that are all the way down to the µs range. This is much different than the more forgiving soft real-time applications that allow for larger signal propagation delays without suffering any negative consequences.

To achieve hard real-time operation, synchronization has to be timed precisely, and consistently, without exception. In order to achieve guaranteed latency, all nodes within the communication chain must have exact time synchronization. It’s important to remember, though, that real-time synchronization should not use Network Time Protocol (NTP) to set the date and time on computers. The recommended protocol for synchronization, and the one that second fieldbus generation systems use, is the IEEE 1588 Precision Time Protocol (PTP), which achieves two-digit nanosecond precision for clocks on different nodes (master and slaves). To avoid synchronization anomalies using this protocol, it is necessary to integrate PTP into the network interface hardware.

In the past, proprietary hardware or protocol extensions have been used by various Industrial Ethernet solutions to achieve real-time operations between the individual nodes. This practice has led to the propagation of incompatible Industrial Ethernet standards that have increased the demand for real-time Ethernet communication standards that are open and can work seamlessly together. This is especially important for factories that are moving more and more to lloT and Industry 4.0 automation, and process control technologies. These factories are customizing their own layer in the automation pyramid, which calls for real-time protocols, such as OPC UA, to achieve standardized data exchange. One just needs to look at the availability of 5G and 10+ GbE networks within factories that allow for the utilization of tactile Internet applications for energy grids and autonomous vehicles used in logistics.

Industrial applications for TSN synchronized tactile Internet are not confined to cloud-based control station technology and remote-controlled robots that carry out tele-surgery. They are increasingly making their way into conventional control solutions that previously relied on classic fieldbuses and Industrial Ethernet applications, due to a significant increase in scalability and bandwidth, as well as the advantages of manufacturer neutrality and higher flexibility

When the time comes to migrate to Industrial Ethernet, or even combining fieldbus and various applications of Industrial Ethernet, problems can be encountered due to constrictions imposed by proprietary solutions. These can include not only licensing issues, but also the inability to achieve trouble-free factory connectivity. Connectivity issues stem from the requirement of having dedicated hardware for most solutions, such as the need for a specific Industrial Ethernet controller. Only one solution, the EtherCAT protocol, stands out in the proprietary forest of Industrial Ethernet solutions by offering real-time networking using standard Ethernet controllers.

Making the hyper jump from Ethernet to Industrial Ethernet

A major hurdle for second fieldbus generation developers was achieving real-time communication for the various real-time classes, with each requiring different response times. This challenge cut across all fieldbus variants due to deterministic transmission rates not being supported by conventional IT Ethernet that complies with IEEE 802.3. Even if we consider that transmission rates are relatively high between variants, irregular delays in data traffic are many times encountered as the resolution of data collisions are controlled by a mechanism that is based on the random principle.

To combat this problem, Real-time Ethernet solutions add their own real-time protocol stacks that are notably smaller in size, thereby preventing collisions of data streams. The protocol stacks are marked in the Ethernet protocol layer as a specific “EtherType”, which allows for prioritization, so data that is not so time-critical can be sent over the mailbox channel in parallel. In this way, real-time traffic is not disturbed, and at the same time guaranteeing consistently seamless Ethernet connectivity for standard TCP/IP communication, such as web servers, e-mail, etc.

Hard real-time applications live up to their name by demanding exact deterministic response times, which many times require almost zero delays and clock cycles that are all the way down to the µs range. This is much different than the more forgiving soft real-time applications that allow for larger signal propagation delays without suffering any negative consequences.

To achieve hard real-time operation, synchronization has to be timed precisely, and consistently, without exception. In order to achieve guaranteed latency, all nodes within the communication chain must have exact time synchronization. It’s important to remember, though, that real-time synchronization should not use Network Time Protocol (NTP) to set the date and time on computers. The recommended protocol for synchronization, and the one that second fieldbus generation systems use, is the IEEE 1588 Precision Time Protocol (PTP), which achieves two-digit nanosecond precision for clocks on different nodes (master and slaves). To avoid synchronization anomalies using this protocol, it is necessary to integrate PTP into the network interface hardware.

In the past, proprietary hardware or protocol extensions have been used by various Industrial Ethernet solutions to achieve real-time operations between the individual nodes. This practice has led to the propagation of incompatible Industrial Ethernet standards that have increased the demand for real-time Ethernet communication standards that are open and can work seamlessly together. This is especially important for factories that are moving more and more to lloT and Industry 4.0 automation, and process control technologies. These factories are customizing their own layer in the automation pyramid, which calls for real-time protocols, such as OPC UA, to achieve standardized data exchange. One just needs to look at the availability of 5G and 10+ GbE networks within factories that allow for the utilization of tactile Internet applications for energy grids and autonomous vehicles used in logistics.

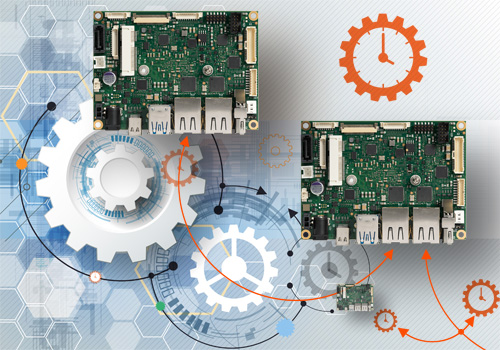

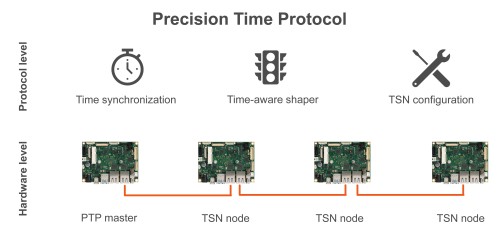

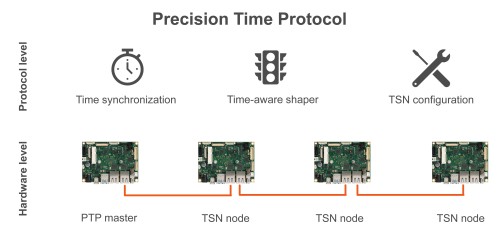

Synchronizing time, scheduling traffic and configuring master and slave devices in the system are core functions of the Time-Sensitive Networking Ethernet standard.

TSN shakes hands with the tactile real-time Internet

The full compatibility of TSN with hard real-time applications is on the horizon. One only needs to look to a few IEEE standards that have already been published by a TSN task group working within the IEEE 802.1, which has been tasked with improving the performance of commercial networks in real-time. One of these standards is the IEEE 802.1Qbv. This standard enables time slicing of processes via a Time-Aware Shaper (TAS) that allows network traffic to be precisely scheduled. Profiles for the cyclic synchronization of TSN nodes is then implemented by the IEEE 802.1AS TSN standard. This solution can now be utilized as a standard component for industrial use, due to the integration of IEEE 802.1AS on a PTP basis for hard real-time applications in standard Intel i210 and i219 Ethernet controllers.

congatec is a good example of how to implement this solution for industrial applications with the use of a i210 controller on a Pico-ITX board with Intel® Atom® E3900 processors. In fact, a proof of concept (PoC) has already been implemented by congatec for integrating the TSN protocol in accordance with the IEEE 1588 PTP specification. As a result of this integration, solutions such as MQTT, DDS, OPC UA and additional industrial Ethernet protocols are fully supported in real time within the upper layers of the communication protocols. congatec’s PoC allows for an Ethernet base load of high resolution video streaming with the parallel generation and transmission of critical real-time data. A demonstration stopped and started IEEE 1588 PTP synchronization using a digital switch so measurements could be taken of distributed devices and fog servers over the Ethernet. The results of the demonstration were impressive and conclusive. cognatec’s PoC has proven that jitter can be reduced to the maximum, all the way down to the highly precise nanosecond scale, regardless of the presence of extremely demanding network loads.

With this successful demonstration in hand, it’s clear we are in for very exciting times ahead and that the time is nigh for blast off of the tactile internet!

Author: Zeljko Loncaric, Marketing Engineer, congatec AG

Synchronizing time, scheduling traffic and configuring master and slave devices in the system are core functions of the Time-Sensitive Networking Ethernet standard.

TSN shakes hands with the tactile real-time Internet

The full compatibility of TSN with hard real-time applications is on the horizon. One only needs to look to a few IEEE standards that have already been published by a TSN task group working within the IEEE 802.1, which has been tasked with improving the performance of commercial networks in real-time. One of these standards is the IEEE 802.1Qbv. This standard enables time slicing of processes via a Time-Aware Shaper (TAS) that allows network traffic to be precisely scheduled. Profiles for the cyclic synchronization of TSN nodes is then implemented by the IEEE 802.1AS TSN standard. This solution can now be utilized as a standard component for industrial use, due to the integration of IEEE 802.1AS on a PTP basis for hard real-time applications in standard Intel i210 and i219 Ethernet controllers.

congatec is a good example of how to implement this solution for industrial applications with the use of a i210 controller on a Pico-ITX board with Intel® Atom® E3900 processors. In fact, a proof of concept (PoC) has already been implemented by congatec for integrating the TSN protocol in accordance with the IEEE 1588 PTP specification. As a result of this integration, solutions such as MQTT, DDS, OPC UA and additional industrial Ethernet protocols are fully supported in real time within the upper layers of the communication protocols. congatec’s PoC allows for an Ethernet base load of high resolution video streaming with the parallel generation and transmission of critical real-time data. A demonstration stopped and started IEEE 1588 PTP synchronization using a digital switch so measurements could be taken of distributed devices and fog servers over the Ethernet. The results of the demonstration were impressive and conclusive. cognatec’s PoC has proven that jitter can be reduced to the maximum, all the way down to the highly precise nanosecond scale, regardless of the presence of extremely demanding network loads.

With this successful demonstration in hand, it’s clear we are in for very exciting times ahead and that the time is nigh for blast off of the tactile internet!

Author: Zeljko Loncaric, Marketing Engineer, congatec AG

Precise time synchronization is an important requirement of the tactile Internet. The Pico-ITX board from congatec is an industrial computer platform that supports Time-Sensitive Networking, which is crucial in ensuring precise synchronization. The Precision Time Protocol handles time synchronization between nodes, with a master responsible for setting the time. The clocks of individual slaves are synchronized within two-digit nanosecond accuracy.

Taking their place is the Industrial Ethernet, a new, second generation of fieldbus that can handle the demands of today’s cutting edge industrial communication systems. The importance and viability of this new generation was confirmed by a 2019 market study from HMS, which found that Industrial Ethernet is supported by about 59% of recently installed nodes for factory automation, but only around 35% of recently installed nodes connect with the classic fieldbus. This is quite a revelation, and certainly a strong confirmation of where things are headed.

Industrial Ethernet applications are extremely powerful and efficient, as a common transmission medium is shared by both real-time and IT data. The advantage of Industrial Ethernet, compared to fieldbus, is that the size of the network and connected devices is practically unlimited. The continuity of data throughout the whole production area is guaranteed, due to network connectivity that is consistent and fully integrated. Securing and firmly controlling the network can be carried out with the implementation of security protocols and IT security management. But fieldbuses are not made obsolete, as they can be used in the field as subordinate networking systems, if the proper gateways are established.

The decline of proprietary standards

A major disadvantage of the current field of Industrial Ethernet variants is their incompatibility with one another, due to each having their own proprietary solution. This same problem is found with the range of available fieldbus systems. If one looks closer at the history of development, it’s no big mystery why this situation exists. When standards for the first fieldbus generation were created, different companies and interest groups introduced differing standards that met their own specific requirements. With the launching of the second fieldbus generation, the same players are still following their own proprietary roadmap.

A few examples that can be mentioned is CANopen, which is an Industrial Ethernet solution based on the CAN fieldbus, as well as the Profibus-based solution called Profinet. Another is Modubus/TCP, which is a version of Modus. More examples exist, but this gives a good idea of the different standards that one is faced with when surveying the second generation of fieldbus solutions.

TSN synchronized TCP/IP network

Precise time synchronization is an important requirement of the tactile Internet. The Pico-ITX board from congatec is an industrial computer platform that supports Time-Sensitive Networking, which is crucial in ensuring precise synchronization. The Precision Time Protocol handles time synchronization between nodes, with a master responsible for setting the time. The clocks of individual slaves are synchronized within two-digit nanosecond accuracy.

Taking their place is the Industrial Ethernet, a new, second generation of fieldbus that can handle the demands of today’s cutting edge industrial communication systems. The importance and viability of this new generation was confirmed by a 2019 market study from HMS, which found that Industrial Ethernet is supported by about 59% of recently installed nodes for factory automation, but only around 35% of recently installed nodes connect with the classic fieldbus. This is quite a revelation, and certainly a strong confirmation of where things are headed.

Industrial Ethernet applications are extremely powerful and efficient, as a common transmission medium is shared by both real-time and IT data. The advantage of Industrial Ethernet, compared to fieldbus, is that the size of the network and connected devices is practically unlimited. The continuity of data throughout the whole production area is guaranteed, due to network connectivity that is consistent and fully integrated. Securing and firmly controlling the network can be carried out with the implementation of security protocols and IT security management. But fieldbuses are not made obsolete, as they can be used in the field as subordinate networking systems, if the proper gateways are established.

The decline of proprietary standards

A major disadvantage of the current field of Industrial Ethernet variants is their incompatibility with one another, due to each having their own proprietary solution. This same problem is found with the range of available fieldbus systems. If one looks closer at the history of development, it’s no big mystery why this situation exists. When standards for the first fieldbus generation were created, different companies and interest groups introduced differing standards that met their own specific requirements. With the launching of the second fieldbus generation, the same players are still following their own proprietary roadmap.

A few examples that can be mentioned is CANopen, which is an Industrial Ethernet solution based on the CAN fieldbus, as well as the Profibus-based solution called Profinet. Another is Modubus/TCP, which is a version of Modus. More examples exist, but this gives a good idea of the different standards that one is faced with when surveying the second generation of fieldbus solutions.

TSN synchronized TCP/IP network

Industrial applications for TSN synchronized tactile Internet are not confined to cloud-based control station technology and remote-controlled robots that carry out tele-surgery. They are increasingly making their way into conventional control solutions that previously relied on classic fieldbuses and Industrial Ethernet applications, due to a significant increase in scalability and bandwidth, as well as the advantages of manufacturer neutrality and higher flexibility

When the time comes to migrate to Industrial Ethernet, or even combining fieldbus and various applications of Industrial Ethernet, problems can be encountered due to constrictions imposed by proprietary solutions. These can include not only licensing issues, but also the inability to achieve trouble-free factory connectivity. Connectivity issues stem from the requirement of having dedicated hardware for most solutions, such as the need for a specific Industrial Ethernet controller. Only one solution, the EtherCAT protocol, stands out in the proprietary forest of Industrial Ethernet solutions by offering real-time networking using standard Ethernet controllers.

Making the hyper jump from Ethernet to Industrial Ethernet

A major hurdle for second fieldbus generation developers was achieving real-time communication for the various real-time classes, with each requiring different response times. This challenge cut across all fieldbus variants due to deterministic transmission rates not being supported by conventional IT Ethernet that complies with IEEE 802.3. Even if we consider that transmission rates are relatively high between variants, irregular delays in data traffic are many times encountered as the resolution of data collisions are controlled by a mechanism that is based on the random principle.

To combat this problem, Real-time Ethernet solutions add their own real-time protocol stacks that are notably smaller in size, thereby preventing collisions of data streams. The protocol stacks are marked in the Ethernet protocol layer as a specific “EtherType”, which allows for prioritization, so data that is not so time-critical can be sent over the mailbox channel in parallel. In this way, real-time traffic is not disturbed, and at the same time guaranteeing consistently seamless Ethernet connectivity for standard TCP/IP communication, such as web servers, e-mail, etc.

Hard real-time applications live up to their name by demanding exact deterministic response times, which many times require almost zero delays and clock cycles that are all the way down to the µs range. This is much different than the more forgiving soft real-time applications that allow for larger signal propagation delays without suffering any negative consequences.

To achieve hard real-time operation, synchronization has to be timed precisely, and consistently, without exception. In order to achieve guaranteed latency, all nodes within the communication chain must have exact time synchronization. It’s important to remember, though, that real-time synchronization should not use Network Time Protocol (NTP) to set the date and time on computers. The recommended protocol for synchronization, and the one that second fieldbus generation systems use, is the IEEE 1588 Precision Time Protocol (PTP), which achieves two-digit nanosecond precision for clocks on different nodes (master and slaves). To avoid synchronization anomalies using this protocol, it is necessary to integrate PTP into the network interface hardware.

In the past, proprietary hardware or protocol extensions have been used by various Industrial Ethernet solutions to achieve real-time operations between the individual nodes. This practice has led to the propagation of incompatible Industrial Ethernet standards that have increased the demand for real-time Ethernet communication standards that are open and can work seamlessly together. This is especially important for factories that are moving more and more to lloT and Industry 4.0 automation, and process control technologies. These factories are customizing their own layer in the automation pyramid, which calls for real-time protocols, such as OPC UA, to achieve standardized data exchange. One just needs to look at the availability of 5G and 10+ GbE networks within factories that allow for the utilization of tactile Internet applications for energy grids and autonomous vehicles used in logistics.

Industrial applications for TSN synchronized tactile Internet are not confined to cloud-based control station technology and remote-controlled robots that carry out tele-surgery. They are increasingly making their way into conventional control solutions that previously relied on classic fieldbuses and Industrial Ethernet applications, due to a significant increase in scalability and bandwidth, as well as the advantages of manufacturer neutrality and higher flexibility

When the time comes to migrate to Industrial Ethernet, or even combining fieldbus and various applications of Industrial Ethernet, problems can be encountered due to constrictions imposed by proprietary solutions. These can include not only licensing issues, but also the inability to achieve trouble-free factory connectivity. Connectivity issues stem from the requirement of having dedicated hardware for most solutions, such as the need for a specific Industrial Ethernet controller. Only one solution, the EtherCAT protocol, stands out in the proprietary forest of Industrial Ethernet solutions by offering real-time networking using standard Ethernet controllers.

Making the hyper jump from Ethernet to Industrial Ethernet

A major hurdle for second fieldbus generation developers was achieving real-time communication for the various real-time classes, with each requiring different response times. This challenge cut across all fieldbus variants due to deterministic transmission rates not being supported by conventional IT Ethernet that complies with IEEE 802.3. Even if we consider that transmission rates are relatively high between variants, irregular delays in data traffic are many times encountered as the resolution of data collisions are controlled by a mechanism that is based on the random principle.

To combat this problem, Real-time Ethernet solutions add their own real-time protocol stacks that are notably smaller in size, thereby preventing collisions of data streams. The protocol stacks are marked in the Ethernet protocol layer as a specific “EtherType”, which allows for prioritization, so data that is not so time-critical can be sent over the mailbox channel in parallel. In this way, real-time traffic is not disturbed, and at the same time guaranteeing consistently seamless Ethernet connectivity for standard TCP/IP communication, such as web servers, e-mail, etc.

Hard real-time applications live up to their name by demanding exact deterministic response times, which many times require almost zero delays and clock cycles that are all the way down to the µs range. This is much different than the more forgiving soft real-time applications that allow for larger signal propagation delays without suffering any negative consequences.

To achieve hard real-time operation, synchronization has to be timed precisely, and consistently, without exception. In order to achieve guaranteed latency, all nodes within the communication chain must have exact time synchronization. It’s important to remember, though, that real-time synchronization should not use Network Time Protocol (NTP) to set the date and time on computers. The recommended protocol for synchronization, and the one that second fieldbus generation systems use, is the IEEE 1588 Precision Time Protocol (PTP), which achieves two-digit nanosecond precision for clocks on different nodes (master and slaves). To avoid synchronization anomalies using this protocol, it is necessary to integrate PTP into the network interface hardware.

In the past, proprietary hardware or protocol extensions have been used by various Industrial Ethernet solutions to achieve real-time operations between the individual nodes. This practice has led to the propagation of incompatible Industrial Ethernet standards that have increased the demand for real-time Ethernet communication standards that are open and can work seamlessly together. This is especially important for factories that are moving more and more to lloT and Industry 4.0 automation, and process control technologies. These factories are customizing their own layer in the automation pyramid, which calls for real-time protocols, such as OPC UA, to achieve standardized data exchange. One just needs to look at the availability of 5G and 10+ GbE networks within factories that allow for the utilization of tactile Internet applications for energy grids and autonomous vehicles used in logistics.

Synchronizing time, scheduling traffic and configuring master and slave devices in the system are core functions of the Time-Sensitive Networking Ethernet standard.

TSN shakes hands with the tactile real-time Internet

The full compatibility of TSN with hard real-time applications is on the horizon. One only needs to look to a few IEEE standards that have already been published by a TSN task group working within the IEEE 802.1, which has been tasked with improving the performance of commercial networks in real-time. One of these standards is the IEEE 802.1Qbv. This standard enables time slicing of processes via a Time-Aware Shaper (TAS) that allows network traffic to be precisely scheduled. Profiles for the cyclic synchronization of TSN nodes is then implemented by the IEEE 802.1AS TSN standard. This solution can now be utilized as a standard component for industrial use, due to the integration of IEEE 802.1AS on a PTP basis for hard real-time applications in standard Intel i210 and i219 Ethernet controllers.

congatec is a good example of how to implement this solution for industrial applications with the use of a i210 controller on a Pico-ITX board with Intel® Atom® E3900 processors. In fact, a proof of concept (PoC) has already been implemented by congatec for integrating the TSN protocol in accordance with the IEEE 1588 PTP specification. As a result of this integration, solutions such as MQTT, DDS, OPC UA and additional industrial Ethernet protocols are fully supported in real time within the upper layers of the communication protocols. congatec’s PoC allows for an Ethernet base load of high resolution video streaming with the parallel generation and transmission of critical real-time data. A demonstration stopped and started IEEE 1588 PTP synchronization using a digital switch so measurements could be taken of distributed devices and fog servers over the Ethernet. The results of the demonstration were impressive and conclusive. cognatec’s PoC has proven that jitter can be reduced to the maximum, all the way down to the highly precise nanosecond scale, regardless of the presence of extremely demanding network loads.

With this successful demonstration in hand, it’s clear we are in for very exciting times ahead and that the time is nigh for blast off of the tactile internet!

Author: Zeljko Loncaric, Marketing Engineer, congatec AG

Synchronizing time, scheduling traffic and configuring master and slave devices in the system are core functions of the Time-Sensitive Networking Ethernet standard.

TSN shakes hands with the tactile real-time Internet

The full compatibility of TSN with hard real-time applications is on the horizon. One only needs to look to a few IEEE standards that have already been published by a TSN task group working within the IEEE 802.1, which has been tasked with improving the performance of commercial networks in real-time. One of these standards is the IEEE 802.1Qbv. This standard enables time slicing of processes via a Time-Aware Shaper (TAS) that allows network traffic to be precisely scheduled. Profiles for the cyclic synchronization of TSN nodes is then implemented by the IEEE 802.1AS TSN standard. This solution can now be utilized as a standard component for industrial use, due to the integration of IEEE 802.1AS on a PTP basis for hard real-time applications in standard Intel i210 and i219 Ethernet controllers.

congatec is a good example of how to implement this solution for industrial applications with the use of a i210 controller on a Pico-ITX board with Intel® Atom® E3900 processors. In fact, a proof of concept (PoC) has already been implemented by congatec for integrating the TSN protocol in accordance with the IEEE 1588 PTP specification. As a result of this integration, solutions such as MQTT, DDS, OPC UA and additional industrial Ethernet protocols are fully supported in real time within the upper layers of the communication protocols. congatec’s PoC allows for an Ethernet base load of high resolution video streaming with the parallel generation and transmission of critical real-time data. A demonstration stopped and started IEEE 1588 PTP synchronization using a digital switch so measurements could be taken of distributed devices and fog servers over the Ethernet. The results of the demonstration were impressive and conclusive. cognatec’s PoC has proven that jitter can be reduced to the maximum, all the way down to the highly precise nanosecond scale, regardless of the presence of extremely demanding network loads.

With this successful demonstration in hand, it’s clear we are in for very exciting times ahead and that the time is nigh for blast off of the tactile internet!

Author: Zeljko Loncaric, Marketing Engineer, congatec AG