Sponsrat innehåll från Siemens Digital Industries Software

Transforming Electronic Systems Design

The electronics industry is entering a new era of digital transformation driven by the urgent need for electronic systems companies to overcome three big design challenges— product, organizational, and process complexity.

These three challenges are looming larger than ever as companies work to create modern-day, even futuristic, products that weld electrical, mechanical, and software design together — and they have to do so under the strain of shrinking design and production schedules and an unprecedented pace of innovation.

Companies can no longer afford the old way of doing things: building multiple prototypes and running them through several test iterations. Indeed, the classic prototyping-dependent approach actually contributes to missed schedules, increased development expenses, and degraded product quality.

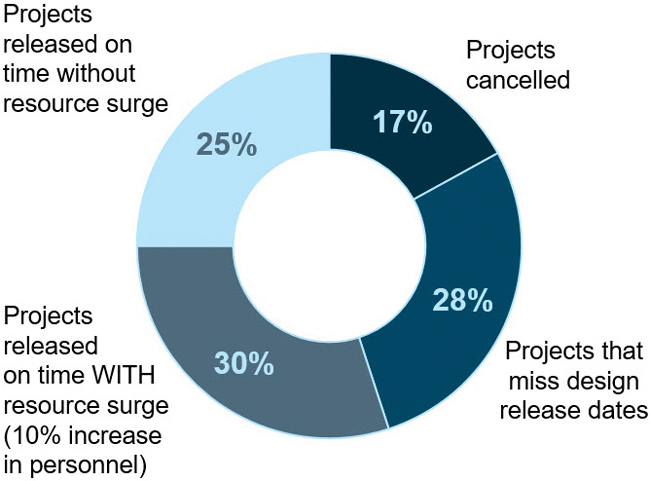

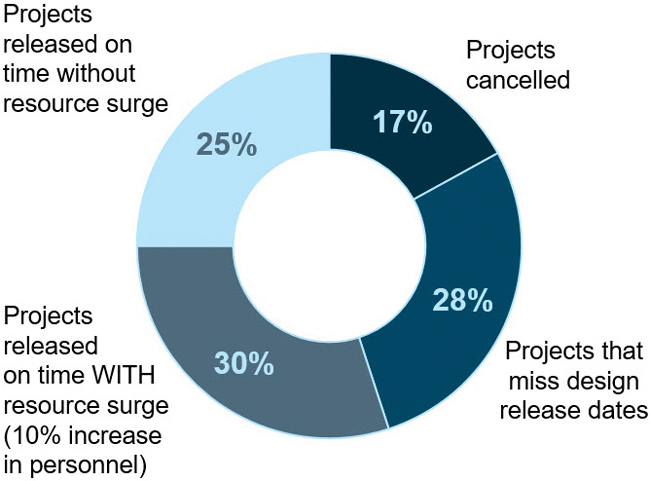

The negative impacts of not adopting new ways of doing business are significant. Recent research by LifeCycle Insights shows that 58 percent of all new product design projects incur unexpected and unbudgeted additional costs and time delays. Only one in four projects actually goes out on time and on budget. To meet schedules, engineering teams often cushion 3-4 respins into their cost and time estimates, thus perpetuating process inefficiencies.

58% of all projects incur additional costs or miss release dates. Source: LifeCycle Insights

The Big Three Complexities

Product complexity has grown significantly with the advent of advanced node ICs, faster DDR memory, and SerDes buses. For example, running signal and power integrity analysis on multi-board designs can be very tricky, and multi-board systems come with difficult connectivity requirements between boards and between boards and mechanical enclosures. Even simpler designs that use the latest generation FPGAs and DDR memory require signal and power integrity analysis. All of this comes at a time of extreme schedule pressure, where the expectation is to get it right the first time, so engineering teams have to get the analysis done quickly and done right. The drive to reduce electronic form factors also drives product complexity, with tighter tolerances between PCBs and enclosures and advanced manufacturing technologies like rigid/flex, HDI, and embedded components.

58% of all projects incur additional costs or miss release dates. Source: LifeCycle Insights

The Big Three Complexities

Product complexity has grown significantly with the advent of advanced node ICs, faster DDR memory, and SerDes buses. For example, running signal and power integrity analysis on multi-board designs can be very tricky, and multi-board systems come with difficult connectivity requirements between boards and between boards and mechanical enclosures. Even simpler designs that use the latest generation FPGAs and DDR memory require signal and power integrity analysis. All of this comes at a time of extreme schedule pressure, where the expectation is to get it right the first time, so engineering teams have to get the analysis done quickly and done right. The drive to reduce electronic form factors also drives product complexity, with tighter tolerances between PCBs and enclosures and advanced manufacturing technologies like rigid/flex, HDI, and embedded components.

Product, organizational, and process complexity lead to increased costs, lower design quality, and missed schedules.

Organizational complexity becomes more entangled as large teams specialize and distributed groups are leveraged to develop a single product. These different design teams often operate independently or in isolation and have poorly defined touch points. Using design tools that cannot share data seamlessly between disciplines often leads to problems found very late in the design cycle or after physical prototypes are built.

Product and organizational complexities also complicate the core processes throughout the entire development flow—from product concept, to architectural decomposition, through all the multiple parallel domains for electronics, mechanical, and software, and finally to manufacturing. Not only do designs need to meet all their functional requirements, the software that interfaces with the hardware must work properly.

Succeeding with Complexity

Overcoming these complexities demands a digital transformation strategy that addresses inefficiencies and optimizes both electronic and multi-domain systems design and verification. By embarking on this digital transformation, companies will break down the barriers between teams, eliminate physical prototypes, and manage IP across the enterprise.

A successful next-generation design platform must support integration, shared data, and improved intelligence. Integration across design processes and disciplines optimizes resources to reduce development time and cost. Sharing context-specific design data reduces design cycles and costs due to fewer data fidelity-driven respins. Improved intelligence provides actionable information and feedback loops to inform cost and resource management decision-making through metrics-driven prescriptive analytics.

In turn, to deliver these three keys to product differentiation, profitability, and beating the competition to market requires five transformation capabilities.

Digitally integrated and optimized multi-domain design

Integration throughout design and into manufacturing is essential for producing products that are high quality, low cost, and on time. Establishing a digitally integrated solution across multiple domains reduces manual intervention, fosters collaboration, and improves transparency across disciplines. It enables efficient, secure, concurrent design across all engineering teams, whether individual contributors work at the same site or across the world. In creating a digital thread between domains, companies establish traceability and interactivity from one domain to the other. Because it provides everyone with visibility to product changes, stakeholders can easily monitor status and performance, audit the change history, and review sign-off reports. A digitally integrated solution enables teams to optimize the costs associated with a project, accelerate design time, manage data integrity, and improve the quality of results.

Model-based systems engineering (MBSE)

A model-based systems engineering approach from product requirements through manufacturing that helps engineering teams solve the multitude of complex and challenging tasks presented by full system design. It allows team members to view the entire system and model pieces of that system individually, earlier in the design flow. It does not matter if those pieces are on the electronics side, the electrical side, the mechanical side, or the software side. By looking at the entire system through a model-based systems perspective, teams can not only look at the electrical and functional trade-offs earlier in the design cycle, but also product trade-offs that might be based on such things as weight, cost, or even available components.

Digital-prototype driven verification

By integrating verification throughout the multi-board electronics design process—starting very early, long before physical prototypes—engineering teams can smooth the entire design process and increase design quality through digital-prototype driven, shift-left verification and cross-domain modeling. Shifting verification to the left in the design flow using automated, integrated tools reduces product schedules and increases the likelihood of on-time product launches. Cost and time are saved by finding problems early, during design, minimizing design iterations and manufacturing respins.

Product, organizational, and process complexity lead to increased costs, lower design quality, and missed schedules.

Organizational complexity becomes more entangled as large teams specialize and distributed groups are leveraged to develop a single product. These different design teams often operate independently or in isolation and have poorly defined touch points. Using design tools that cannot share data seamlessly between disciplines often leads to problems found very late in the design cycle or after physical prototypes are built.

Product and organizational complexities also complicate the core processes throughout the entire development flow—from product concept, to architectural decomposition, through all the multiple parallel domains for electronics, mechanical, and software, and finally to manufacturing. Not only do designs need to meet all their functional requirements, the software that interfaces with the hardware must work properly.

Succeeding with Complexity

Overcoming these complexities demands a digital transformation strategy that addresses inefficiencies and optimizes both electronic and multi-domain systems design and verification. By embarking on this digital transformation, companies will break down the barriers between teams, eliminate physical prototypes, and manage IP across the enterprise.

A successful next-generation design platform must support integration, shared data, and improved intelligence. Integration across design processes and disciplines optimizes resources to reduce development time and cost. Sharing context-specific design data reduces design cycles and costs due to fewer data fidelity-driven respins. Improved intelligence provides actionable information and feedback loops to inform cost and resource management decision-making through metrics-driven prescriptive analytics.

In turn, to deliver these three keys to product differentiation, profitability, and beating the competition to market requires five transformation capabilities.

Digitally integrated and optimized multi-domain design

Integration throughout design and into manufacturing is essential for producing products that are high quality, low cost, and on time. Establishing a digitally integrated solution across multiple domains reduces manual intervention, fosters collaboration, and improves transparency across disciplines. It enables efficient, secure, concurrent design across all engineering teams, whether individual contributors work at the same site or across the world. In creating a digital thread between domains, companies establish traceability and interactivity from one domain to the other. Because it provides everyone with visibility to product changes, stakeholders can easily monitor status and performance, audit the change history, and review sign-off reports. A digitally integrated solution enables teams to optimize the costs associated with a project, accelerate design time, manage data integrity, and improve the quality of results.

Model-based systems engineering (MBSE)

A model-based systems engineering approach from product requirements through manufacturing that helps engineering teams solve the multitude of complex and challenging tasks presented by full system design. It allows team members to view the entire system and model pieces of that system individually, earlier in the design flow. It does not matter if those pieces are on the electronics side, the electrical side, the mechanical side, or the software side. By looking at the entire system through a model-based systems perspective, teams can not only look at the electrical and functional trade-offs earlier in the design cycle, but also product trade-offs that might be based on such things as weight, cost, or even available components.

Digital-prototype driven verification

By integrating verification throughout the multi-board electronics design process—starting very early, long before physical prototypes—engineering teams can smooth the entire design process and increase design quality through digital-prototype driven, shift-left verification and cross-domain modeling. Shifting verification to the left in the design flow using automated, integrated tools reduces product schedules and increases the likelihood of on-time product launches. Cost and time are saved by finding problems early, during design, minimizing design iterations and manufacturing respins.

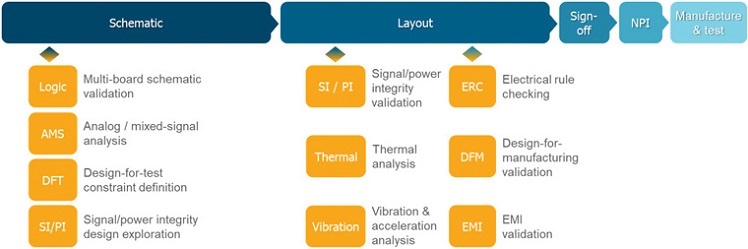

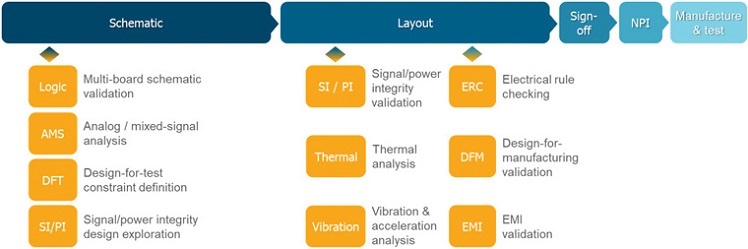

Teams can catch more errors, earlier, by integrating verification throughout the design process

Capacity, performance, productivity, and efficiency

Process automation, abstraction, reuse, and scalable tool capacity sustain engineering productivity and process efficiency regardless of design complexity, so design and process complexity won’t bog everything down. A next-generation systems design platform must provide scalability so it can be tailored to the user’s needs based on their organization’s size, challenges, and design team expertise. Automation of several key steps throughout the process — from schematic to layout and even verification — enables designers to be more productive while ensuring they are still in control of the design.

Supplier strength and credibility

To facilitate the successful adoption of a digital transformation strategy, companies need tools backed by a global supplier that can develop, enhance, and support next-generation design platforms.

Read the full whitepaper which describes these five pillars and shares how Siemens EDA, a part of Siemens Digital Industries Software, can help organizations put them in place, so that companies can turn the promises of the coming digital transformation era into real opportunities today.

Teams can catch more errors, earlier, by integrating verification throughout the design process

Capacity, performance, productivity, and efficiency

Process automation, abstraction, reuse, and scalable tool capacity sustain engineering productivity and process efficiency regardless of design complexity, so design and process complexity won’t bog everything down. A next-generation systems design platform must provide scalability so it can be tailored to the user’s needs based on their organization’s size, challenges, and design team expertise. Automation of several key steps throughout the process — from schematic to layout and even verification — enables designers to be more productive while ensuring they are still in control of the design.

Supplier strength and credibility

To facilitate the successful adoption of a digital transformation strategy, companies need tools backed by a global supplier that can develop, enhance, and support next-generation design platforms.

Read the full whitepaper which describes these five pillars and shares how Siemens EDA, a part of Siemens Digital Industries Software, can help organizations put them in place, so that companies can turn the promises of the coming digital transformation era into real opportunities today.

58% of all projects incur additional costs or miss release dates. Source: LifeCycle Insights

The Big Three Complexities

Product complexity has grown significantly with the advent of advanced node ICs, faster DDR memory, and SerDes buses. For example, running signal and power integrity analysis on multi-board designs can be very tricky, and multi-board systems come with difficult connectivity requirements between boards and between boards and mechanical enclosures. Even simpler designs that use the latest generation FPGAs and DDR memory require signal and power integrity analysis. All of this comes at a time of extreme schedule pressure, where the expectation is to get it right the first time, so engineering teams have to get the analysis done quickly and done right. The drive to reduce electronic form factors also drives product complexity, with tighter tolerances between PCBs and enclosures and advanced manufacturing technologies like rigid/flex, HDI, and embedded components.

58% of all projects incur additional costs or miss release dates. Source: LifeCycle Insights

The Big Three Complexities

Product complexity has grown significantly with the advent of advanced node ICs, faster DDR memory, and SerDes buses. For example, running signal and power integrity analysis on multi-board designs can be very tricky, and multi-board systems come with difficult connectivity requirements between boards and between boards and mechanical enclosures. Even simpler designs that use the latest generation FPGAs and DDR memory require signal and power integrity analysis. All of this comes at a time of extreme schedule pressure, where the expectation is to get it right the first time, so engineering teams have to get the analysis done quickly and done right. The drive to reduce electronic form factors also drives product complexity, with tighter tolerances between PCBs and enclosures and advanced manufacturing technologies like rigid/flex, HDI, and embedded components.

Product, organizational, and process complexity lead to increased costs, lower design quality, and missed schedules.

Organizational complexity becomes more entangled as large teams specialize and distributed groups are leveraged to develop a single product. These different design teams often operate independently or in isolation and have poorly defined touch points. Using design tools that cannot share data seamlessly between disciplines often leads to problems found very late in the design cycle or after physical prototypes are built.

Product and organizational complexities also complicate the core processes throughout the entire development flow—from product concept, to architectural decomposition, through all the multiple parallel domains for electronics, mechanical, and software, and finally to manufacturing. Not only do designs need to meet all their functional requirements, the software that interfaces with the hardware must work properly.

Succeeding with Complexity

Overcoming these complexities demands a digital transformation strategy that addresses inefficiencies and optimizes both electronic and multi-domain systems design and verification. By embarking on this digital transformation, companies will break down the barriers between teams, eliminate physical prototypes, and manage IP across the enterprise.

A successful next-generation design platform must support integration, shared data, and improved intelligence. Integration across design processes and disciplines optimizes resources to reduce development time and cost. Sharing context-specific design data reduces design cycles and costs due to fewer data fidelity-driven respins. Improved intelligence provides actionable information and feedback loops to inform cost and resource management decision-making through metrics-driven prescriptive analytics.

In turn, to deliver these three keys to product differentiation, profitability, and beating the competition to market requires five transformation capabilities.

Digitally integrated and optimized multi-domain design

Integration throughout design and into manufacturing is essential for producing products that are high quality, low cost, and on time. Establishing a digitally integrated solution across multiple domains reduces manual intervention, fosters collaboration, and improves transparency across disciplines. It enables efficient, secure, concurrent design across all engineering teams, whether individual contributors work at the same site or across the world. In creating a digital thread between domains, companies establish traceability and interactivity from one domain to the other. Because it provides everyone with visibility to product changes, stakeholders can easily monitor status and performance, audit the change history, and review sign-off reports. A digitally integrated solution enables teams to optimize the costs associated with a project, accelerate design time, manage data integrity, and improve the quality of results.

Model-based systems engineering (MBSE)

A model-based systems engineering approach from product requirements through manufacturing that helps engineering teams solve the multitude of complex and challenging tasks presented by full system design. It allows team members to view the entire system and model pieces of that system individually, earlier in the design flow. It does not matter if those pieces are on the electronics side, the electrical side, the mechanical side, or the software side. By looking at the entire system through a model-based systems perspective, teams can not only look at the electrical and functional trade-offs earlier in the design cycle, but also product trade-offs that might be based on such things as weight, cost, or even available components.

Digital-prototype driven verification

By integrating verification throughout the multi-board electronics design process—starting very early, long before physical prototypes—engineering teams can smooth the entire design process and increase design quality through digital-prototype driven, shift-left verification and cross-domain modeling. Shifting verification to the left in the design flow using automated, integrated tools reduces product schedules and increases the likelihood of on-time product launches. Cost and time are saved by finding problems early, during design, minimizing design iterations and manufacturing respins.

Product, organizational, and process complexity lead to increased costs, lower design quality, and missed schedules.

Organizational complexity becomes more entangled as large teams specialize and distributed groups are leveraged to develop a single product. These different design teams often operate independently or in isolation and have poorly defined touch points. Using design tools that cannot share data seamlessly between disciplines often leads to problems found very late in the design cycle or after physical prototypes are built.

Product and organizational complexities also complicate the core processes throughout the entire development flow—from product concept, to architectural decomposition, through all the multiple parallel domains for electronics, mechanical, and software, and finally to manufacturing. Not only do designs need to meet all their functional requirements, the software that interfaces with the hardware must work properly.

Succeeding with Complexity

Overcoming these complexities demands a digital transformation strategy that addresses inefficiencies and optimizes both electronic and multi-domain systems design and verification. By embarking on this digital transformation, companies will break down the barriers between teams, eliminate physical prototypes, and manage IP across the enterprise.

A successful next-generation design platform must support integration, shared data, and improved intelligence. Integration across design processes and disciplines optimizes resources to reduce development time and cost. Sharing context-specific design data reduces design cycles and costs due to fewer data fidelity-driven respins. Improved intelligence provides actionable information and feedback loops to inform cost and resource management decision-making through metrics-driven prescriptive analytics.

In turn, to deliver these three keys to product differentiation, profitability, and beating the competition to market requires five transformation capabilities.

Digitally integrated and optimized multi-domain design

Integration throughout design and into manufacturing is essential for producing products that are high quality, low cost, and on time. Establishing a digitally integrated solution across multiple domains reduces manual intervention, fosters collaboration, and improves transparency across disciplines. It enables efficient, secure, concurrent design across all engineering teams, whether individual contributors work at the same site or across the world. In creating a digital thread between domains, companies establish traceability and interactivity from one domain to the other. Because it provides everyone with visibility to product changes, stakeholders can easily monitor status and performance, audit the change history, and review sign-off reports. A digitally integrated solution enables teams to optimize the costs associated with a project, accelerate design time, manage data integrity, and improve the quality of results.

Model-based systems engineering (MBSE)

A model-based systems engineering approach from product requirements through manufacturing that helps engineering teams solve the multitude of complex and challenging tasks presented by full system design. It allows team members to view the entire system and model pieces of that system individually, earlier in the design flow. It does not matter if those pieces are on the electronics side, the electrical side, the mechanical side, or the software side. By looking at the entire system through a model-based systems perspective, teams can not only look at the electrical and functional trade-offs earlier in the design cycle, but also product trade-offs that might be based on such things as weight, cost, or even available components.

Digital-prototype driven verification

By integrating verification throughout the multi-board electronics design process—starting very early, long before physical prototypes—engineering teams can smooth the entire design process and increase design quality through digital-prototype driven, shift-left verification and cross-domain modeling. Shifting verification to the left in the design flow using automated, integrated tools reduces product schedules and increases the likelihood of on-time product launches. Cost and time are saved by finding problems early, during design, minimizing design iterations and manufacturing respins.

Teams can catch more errors, earlier, by integrating verification throughout the design process

Capacity, performance, productivity, and efficiency

Process automation, abstraction, reuse, and scalable tool capacity sustain engineering productivity and process efficiency regardless of design complexity, so design and process complexity won’t bog everything down. A next-generation systems design platform must provide scalability so it can be tailored to the user’s needs based on their organization’s size, challenges, and design team expertise. Automation of several key steps throughout the process — from schematic to layout and even verification — enables designers to be more productive while ensuring they are still in control of the design.

Supplier strength and credibility

To facilitate the successful adoption of a digital transformation strategy, companies need tools backed by a global supplier that can develop, enhance, and support next-generation design platforms.

Read the full whitepaper which describes these five pillars and shares how Siemens EDA, a part of Siemens Digital Industries Software, can help organizations put them in place, so that companies can turn the promises of the coming digital transformation era into real opportunities today.

Teams can catch more errors, earlier, by integrating verification throughout the design process

Capacity, performance, productivity, and efficiency

Process automation, abstraction, reuse, and scalable tool capacity sustain engineering productivity and process efficiency regardless of design complexity, so design and process complexity won’t bog everything down. A next-generation systems design platform must provide scalability so it can be tailored to the user’s needs based on their organization’s size, challenges, and design team expertise. Automation of several key steps throughout the process — from schematic to layout and even verification — enables designers to be more productive while ensuring they are still in control of the design.

Supplier strength and credibility

To facilitate the successful adoption of a digital transformation strategy, companies need tools backed by a global supplier that can develop, enhance, and support next-generation design platforms.

Read the full whitepaper which describes these five pillars and shares how Siemens EDA, a part of Siemens Digital Industries Software, can help organizations put them in place, so that companies can turn the promises of the coming digital transformation era into real opportunities today.