Boundless freedom for edge servers

Edge servers process data at the edge of communication networks instead of in central clouds. This enables interaction with clients of all kinds without delay or in real time but presents manufacturers of server, networking and storage technologies with major challenges. Until now, they used to develop standardized rack solutions for their systems, with active ventilation concepts and powerful air-conditioning technology to control the thermal management of the racks and the air-conditioning in the server rooms. However, such an approach is often no longer a good fit for the edge server technology of today.

The American Society of Heating, Refrigerating and Air-Conditioning Engineers, or ASHRAE for short, has looked thoroughly at the question of how to best install edge server performance in harsh environments. So, from the perspective of the associated heating, cooling, ventilation and air-conditioning companies, there are already quite plausible recommendations on how to design edge data centers with high-performance air-conditioning and the best possible insulation to protect them from heat and cold.

Freeing edge servers from the shackles of air-conditioning

However, ASHRAE proposes a maximum permissible temperature fluctuation of 20°C within one hour and a maximum of 5°C in 15 minutes for edge data centers. This requires complex air-conditioning technology and is therefore very difficult to implement. But not only that; adhering to these guidelines is near impossible, especially during maintenance work in edge data centers that are smaller than a telephone booth, because such solutions must be opened for maintenance at any ambient temperature. It is simply not possible to slip into such systems via a climate control chamber and quickly close the door again before carrying out maintenance work in the fully air-conditioned edge server room.

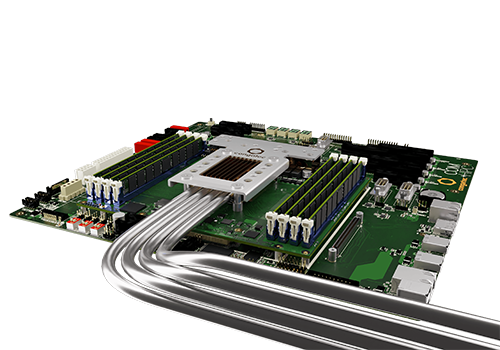

Standard motherboard designs usually only support standard interfaces. As this doesn’t take industrial requirements into account, their suitability as edge servers for the Internet of Things is limited. And as a rule, they are neither designed for the extended temperature range of -40°C to +85°C nor do they guarantee long-term availability of 7 to 15 years. With Server-on-Modules, however, it is possible to use the mechanics of these form factors and design a carrier board that executes the desired interfaces where they are required.

Edge servers and data centers operating in harsh environments therefore need system designs that can cope with greater temperature fluctuations and a much wider temperature range than the 0‑40°C that is common for indoor IT. In industrial environments, embedded system designs can be exposed to ambient temperatures ranging from an arctic -40°C to a searing hot 85°C. Which means each component must be hardened.

Rugged designs reduce air-conditioning costs

The most neuralgic point in the design of edge server, networking and storage technologies is the choice of processor technology. The decision that stands and falls with this choice is whether to follow the ASHRAE recommendations and invest massively in air-conditioning technology and insulation, which comes with high investment and operating costs for secondary energy. Or whether to develop systems that don’t need any of that because they work reliably even in extreme temperatures and can therefore be implemented in harsh environments much more cheaply – from factory installations to outdoor communications, video surveillance and other critical infrastructure equipment to servers in mobile systems ranging from trains and airplanes to self-driving shuttle buses in smart cities.

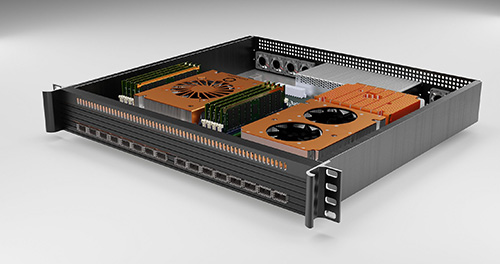

Thanks to the Intel Xeon D processors, there is now a very powerful server technology that is qualified for use in extreme temperature ranges from -40°C to 85°C. Even ultra high-performance server designs are no longer constrained by the tight thermal restrictions of air-conditioned server rooms. Ultimately, they can be deployed wherever latency-free massive data throughput is required at the edge of the Internet of Things and in Industry 4.0 factories.

COM-HPC edge server designs are not limited to single-module concepts. The standard also explicitly supports multi-module carriers with heterogeneous COM-HPC module configurations that integrate e.g. FPGAs or GPGPU accelerators. A mix of COM-HPC Server and COM-HPC Client modules on one board is also possible.

Developers of embedded computing technologies such as congatec have decades of experience in the design of such systems. They have long been integrating standard PC technologies such as Intel Core processors into embedded systems in a way that is suitable for industrial use. They know the requirements and certification standards of a wide range of industries inside out; and they are used to designing their systems for long-term availability in order to meet industry requirements and to be able to supply OEM solutions with identical board configurations for 7, 10 or 15 years. They also know that industrial applications differ significantly from standard system designs for the office environment, because industrial applications always require a greater or lesser degree of customization, which makes modular designs that deploy Computer-on-Modules the ideal way to develop boards. They have also learned that standardization is key, which is why they helped to create globally recognized standards for such modules.

Reaching the goal faster with standards

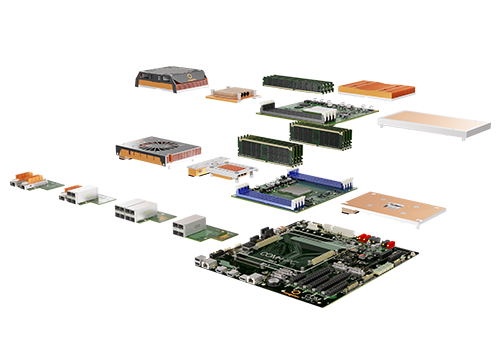

With the COM-HPC Server specification in place, and the launch of the Intel Xeon D processors, this bundled expertise has now been transposed to industrial edge server designs. For the first time, developers have access to real products. The advantage of these standardized COM‑HPC Server-on-Modules is that developers can integrate them into their custom carrier boards as application-ready embedded computing logic. This means they don’t have to concern themselves with basic processor technology issues, but only deal with the application-specific positioning of the board components and execute the interfaces at the right place on the carrier board .

Congatec’s high-performance ecosystem for COM-HPC Server offers everything designers need to develop dedicated edge servers with application-specific interface layouts.

A milestone for real-time edge server designs

In fact, the Ice Lake D based COM-HPC Server-on-Modules set a triple milestone: First, because extended temperature range support means Intel Xeon D Server-on-Modules are no longer limited to standard industrial applications but also target outdoor and automotive environments. Second, the world’s first COM-HPC Server-on-Modules increase the number of available cores to 20 for the first time; with up to 8 DRAM sockets, this provides massively more memory bandwidth than Server-on-Modules based on other PICMG specifications. Third, these server modules are real-time capable, both in terms of processor cores and TCC/TSN-enabled real-time Ethernet, which is essential for digitalized IIoT and Industry 4.0 projects.

To be able to implement server balancing and server consolidation services for deterministic real-time edge server installations, where diverse real-time applications operate independently of each other on a single edge server, it is helpful if the platforms support real-time-capable virtual machines, as the RTS Hypervisor from Real-Time Systems does, for example. This allows Industry 4.0 factories to host heterogeneous real-time applications on a single server platform at the edge of their private 5G networks, and to allocate exclusive system resources to the individual processes. Server-on-Modules from congatec are pre-qualified for such services. Custom installations with all the necessary parameterizations can be included in the standard services that congatec offers for the COM-HPC modules.

The modules further impress with a comprehensive server-grade feature set: For mission-critical designs, they offer powerful hardware security functions such as Intel Boot Guard, Intel Total Memory Encryption - Multi-Tenant (Intel TME-MT) and Intel Software Guard Extensions (Intel SGX). For best RAS capabilities, the processor modules integrate the Intel ME Manageability Engine and support remote hardware management features such as IPMI and redfish. In fact, there is another PICMG specification that ensures the interoperability of such implementations, and the training program of the congatec academy also covers this aspect.

For more information on COM-HPC Server, please visit https://www.congatec.com/en/technologies/com-hpc-server/

About congatec

congatec is a rapidly growing technology company focusing on embedded and edge computing products and services. The high-performance computer modules are used in a wide range of applications and devices in industrial automation, medical technology, transportation, telecommunications and many other verticals. Backed by controlling shareholder DBAG Fund VIII, a German midmarket fund focusing on growing industrial businesses, congatec has the financing and M&A experience to take advantage of these expanding market opportunities. congatec is the global market leader in the computer-on-modules segment with an excellent customer base from start-ups to international blue chip companies. Founded in 2004 and headquartered in Deggendorf, Germany, the company reached sales of 127.5 million US dollars in 2020. More information is available on our website at www.congatec.com or via LinkedIn, Twitter and YouTube.